Service & Repair

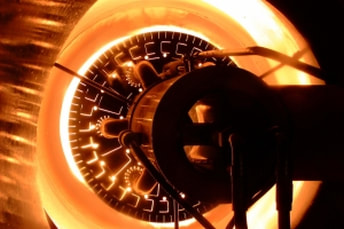

Service breakdown and contract work is limited to Namibia and the personnel travel a far afield as Angola . Our staff attends training courses throughout the year not only on the Company's primary products but also to make themselves conversant in related products. On the burner side we work only on Riello and Limpsfield burners. As to boilers , the staff is competent on both steam and hot water boilers and we are Approved Inspection Authority (A.I.A) by the Namibian Ministry of Works and Labour. The service department is on standby 24/7 throughout the year and the technician on duty can be reached by dialing all hours number +26464204327.

Service breakdown and contract work is limited to Namibia and the personnel travel a far afield as Angola . Our staff attends training courses throughout the year not only on the Company's primary products but also to make themselves conversant in related products. On the burner side we work only on Riello and Limpsfield burners. As to boilers , the staff is competent on both steam and hot water boilers and we are Approved Inspection Authority (A.I.A) by the Namibian Ministry of Works and Labour. The service department is on standby 24/7 throughout the year and the technician on duty can be reached by dialing all hours number +26464204327.

Combustion Efficiency Audits

To enable customers to gain an understanding of the current operation of their boiler plant and the potential savings that can be made through the installation of Autoflame equipment, Autoflame have developed a rigorous combustion efficiency audit. At the heart of the audit process is Autoflame's emissions calculator software. In carrying out a combustion efficiency audit a site visit is conducted to review the boiler plant and take emissions readings from it. Emissions readings are then entered into the emissions calculator software and accurate forecasts of potential savings generated.

To enable customers to gain an understanding of the current operation of their boiler plant and the potential savings that can be made through the installation of Autoflame equipment, Autoflame have developed a rigorous combustion efficiency audit. At the heart of the audit process is Autoflame's emissions calculator software. In carrying out a combustion efficiency audit a site visit is conducted to review the boiler plant and take emissions readings from it. Emissions readings are then entered into the emissions calculator software and accurate forecasts of potential savings generated.

Training

Rentech is fully committed to after-sales service and also offers on-site training to your employees on working with newly-installed equipment. Basic trouble shooting and problem-solving is covered to empower other employees to better understand the new system. The customer can request the type of training to be done and the relevant Certificates will be issued upon completion.

Rentech is fully committed to after-sales service and also offers on-site training to your employees on working with newly-installed equipment. Basic trouble shooting and problem-solving is covered to empower other employees to better understand the new system. The customer can request the type of training to be done and the relevant Certificates will be issued upon completion.

Outsourcing / Renting & Purchasing

If you are looking to manage your boiler house costs , it's time to leave it up to us. Rentech is now offering customers the option to outsource their steam production, which means that the operation and maintenance are done by our qualified team.

We also offer payment terms for all our new boiler installations.

If you are looking to manage your boiler house costs , it's time to leave it up to us. Rentech is now offering customers the option to outsource their steam production, which means that the operation and maintenance are done by our qualified team.

We also offer payment terms for all our new boiler installations.

Manufacturing

Rentech uses Solid Works as a design tool and CNC plasma cutter for all our in house designed products. Currently we manufacture the following products in house which are our own designs :

1. Electrical & Steam Heavy Furnace Fuel (HFO) heaters.

2. Incinerators with built in hot water heat recovery.

3. Electrical panels, which all come with complete set of electrical drawings. We use SEE Electrical software for all our electrical drawings.

Rentech uses Solid Works as a design tool and CNC plasma cutter for all our in house designed products. Currently we manufacture the following products in house which are our own designs :

1. Electrical & Steam Heavy Furnace Fuel (HFO) heaters.

2. Incinerators with built in hot water heat recovery.

3. Electrical panels, which all come with complete set of electrical drawings. We use SEE Electrical software for all our electrical drawings.